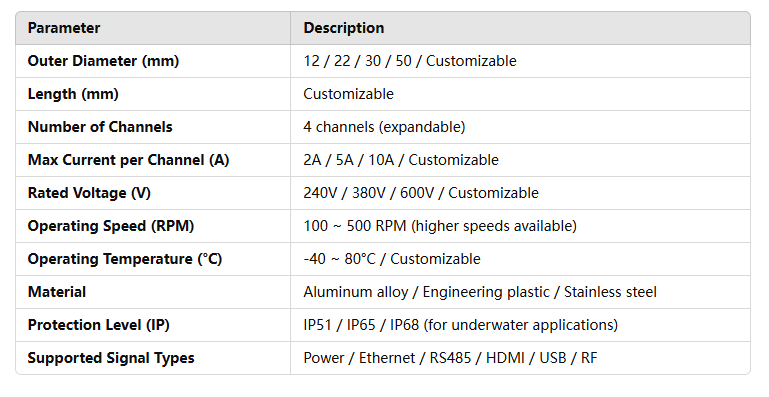

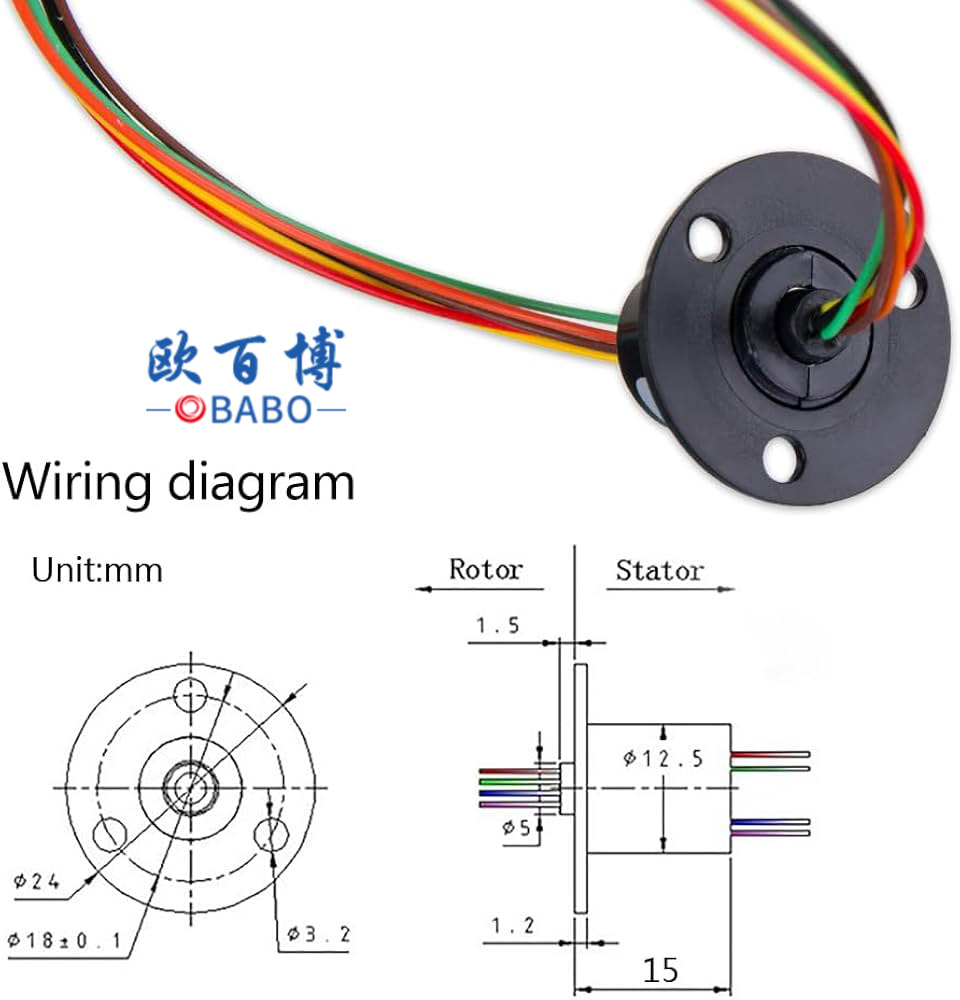

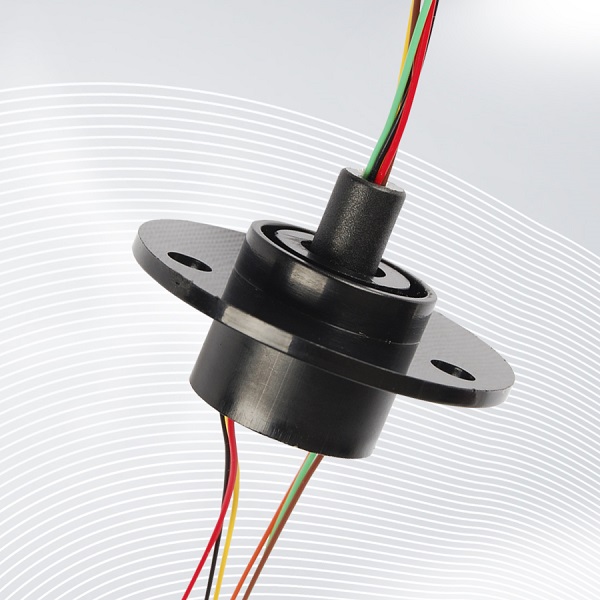

4 Wire Slip Ring is an electric slip ring used to transmit current or signal to rotating equipment. It is widely used in robots, camera equipment, wind power generation, automation machinery, etc. Its core advantages include low resistance, stable transmission, and long life, which can ensure seamless power supply or signal transmission of the device during continuous rotation. Common specifications include rated current 2A-10A, working voltage 12V-380V, and rotation speed 300-600RPM.

Features and Benefits

360° continuous rotation:

The 360° continuous rotation feature of the Compact 4 Wire Slip Ring allows the device to maintain stable power and signal transmission during rotation, avoiding interference or damage caused by kinking or stretching of traditional cables. It ensures unlimited rotation without entanglement problems, reduces equipment wear and failure, and extends service life. Through low-friction design, it provides smooth rotation and reduces energy loss. It is suitable for a variety of applications such as robots, wind power generation, and automation equipment, which significantly improves equipment reliability and maintenance efficiency.

High Performance and Quality:

The 4 Wire Slip Ring has high performance and high quality features, including low contact resistance and high conductivity, ensuring stable power and signal transmission. Gold-gold or silver-silver contact materials are used to improve durability and reduce wear and extend service life. Low friction design ensures smooth rotation and reduces energy consumption. Anti-electromagnetic interference (EMI) ensures signal integrity. Its high temperature resistance and corrosion resistance are suitable for harsh environments and provide a high level of protection. It is widely used in industries, robots, and medical equipment.

Customizable specifications:

The customizable specifications of 4 Wire Slip Ring include current, voltage, signal type, size and installation method, which can be adjusted according to different application requirements. It supports multiple signal transmissions, such as CAN, RS485, USB, etc., and is suitable for high power and high frequency transmission. Customizable working environment parameters such as temperature range (-40°C to 85°C) and protection level (IP65, IP67, etc.) ensure stable operation in harsh environments. The material, durability and special design (such as low torque, anti-interference) of the slip ring can be customized according to requirements.

Installation compatibility:

The installation compatibility of 4 Wire Slip Ring features multiple installation methods, such as flange, hollow shaft, end fixing and axial installation, to adapt to different equipment and space requirements. The compact design is suitable for small equipment, supports multi-channel transmission, and is suitable for complex applications. Its protection level (such as IP65, IP67) ensures stable operation in harsh environments, adapts to various size, shape and material requirements, and is convenient for integration with various types of equipment.

Customers can request customization based on specific application needs. Key customizable parameters include:

Advantages of 4 Wire Slip Ring

High stability

4 Wire Slip Ring has high stability, uses precious metal or gold-plated contact materials, low contact resistance (<10mω), to="" ensure="" stable="" power="" and="" signal="" transmission.="" advanced="" contact="" technology="" reduces="" electrical="" noise="">

High compatibility

4 Channel Slip Ring is compatible with a variety of signal types (power, Ethernet, USB, HDMI, RS485, RF, etc.), supports different voltages (240V/380V/600V) and currents (2A/5A/10A+), and is suitable for a variety of devices. Provides multiple installation methods such as flange, shaft, hollow shaft, etc., adapts to -40°C—80°C environment, supports IP51/IP68 protection level. Adapts to low-speed and high-speed rotating equipment, modular design is easy to customize, and is widely used in industrial automation, robotics, medical, wind power and other fields.

Simple maintenance

4 Wire Slip Ring uses precious metal or gold-plated contacts, which are wear-resistant and have a lifespan of up to 10 million rotations, reducing the frequency of replacement. Low contact resistance (<10mω), stable="" signal="">

4 Application scope of Wire Slip Ring

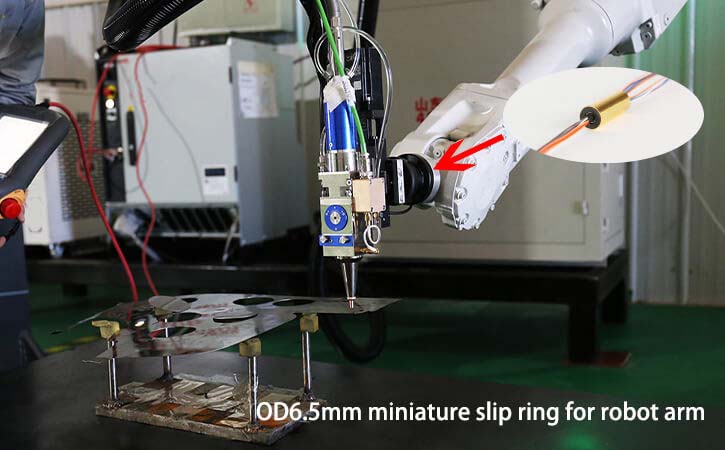

4 Wire Slip Ring for Robotics

4 Wire Slip Ring is widely used in robots for joint rotation, AGV/AMR, robot end effectors, rotating platforms, etc., to solve power and signal transmission problems and avoid cable entanglement. It is used in robotic arms, automation equipment, intelligent monitoring, medical robots, etc. to ensure 360° continuous rotation, transmit power, data, sensor signals, and improve the flexibility, stability and reliability of equipment.

Small 4 Wire Slip Ring for CCTV Cameras

Small 4 Wire Slip Rings for CCTV cameras enable continuous 360° rotation, ensuring uninterrupted power and signal transmission for PTZ cameras. Compact in design, they fit into space-constrained mounts and transmit video, control signals, and power without cable twisting. With low maintenance, long lifespan, and high durability, they are ideal for surveillance systems, offering reliable performance in various environments.

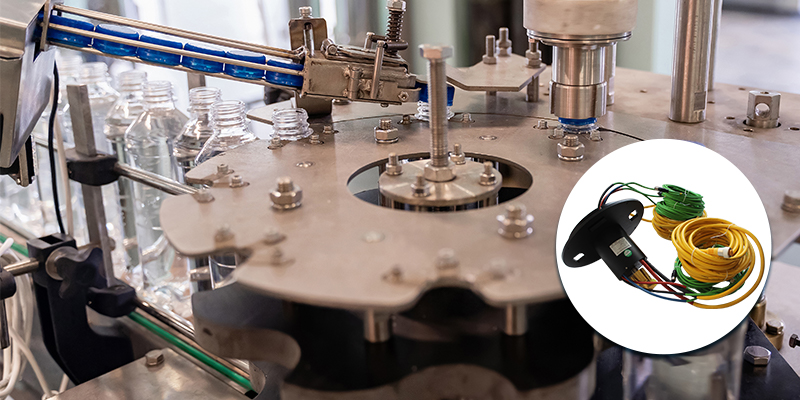

4 Wire Conductive Slip Ring for Automation

4 wires Conductive Slip Rings in automation systems enable continuous transmission of power, data, and control signals between rotating and stationary parts. They offer reliable, low-resistance connections, reducing cable wear and improving system longevity. Compact and easy to integrate, these slip rings are ideal for robotics, CNC machines, conveyor belts, and packaging equipment, ensuring smooth, efficient operation with minimal maintenance.

OBABO is a 4 Wire Slip Ring manufacturer, and here are the key maintenance recommendations for 4 Wire Slip Ring for customers:

1. Regular Cleaning and Inspection

Clean the slip ring regularly to remove dust, dirt and debris that may cause friction or hinder smooth rotation.

Inspect the brushes and rings for wear. If the brushes show signs of excessive wear or uneven contact, consider replacing them to prevent signal degradation.

2. Monitor the electrical connection

Inspect the electrical contact points for signs of corrosion or damage. Gold or precious metal contacts are very durable, but it is still important to monitor any signs of degradation over time.

Measure the contact resistance regularly to ensure it remains low (ideally below 10mΩ).

3. Lubrication (if applicable)

Some slip rings may require regular lubrication, especially in models using self-lubricating materials. However, over-lubrication should be avoided as lubrication can cause dust and debris to accumulate.

If lubrication is required, make sure to use only the recommended lubricant type to avoid damage to the components.

4. Environmental protection

Ensure the slip ring is installed in an environment that meets its IP rating (e.g. IP65 or IP68). If used in harsh conditions (e.g. high humidity, dust, or extreme temperatures), ensure it is installed in a protective housing to avoid environmental damage.

5. Check for overload

Avoid exceeding the maximum current rating of each channel (e.g. 2A, 5A, 10A). Overload can cause overheating, which can damage internal components and shorten the life of the slip ring.

Ensure proper heat dissipation and ventilation if the system is frequently subjected to high current loads.

6. Regular functional testing

Test the rotation function regularly to ensure smooth and continuous operation without jitter or noise.

Test signal integrity (video, data, power) regularly to confirm stable transmission and detect potential problems before they affect performance.

FAQ

What is 4 Wire Slip Ring?

A 4 Wire Slip Ring is an electrical connection component that is mainly used in rotating equipment to transmit current or signals. It contacts the brushes through multiple conductive rings to ensure stable transmission of current or signals during the rotation of the equipment.

How much current can a 4 Wire Slip Ring carry?

The carrying current of a 4 Wire Slip Ring is usually between 2A and 10A, depending on the model and manufacturer's requirements. Some customized models can carry higher currents.

How to choose a suitable 4 Wire Slip Ring?

When choosing, you need to consider the current capacity, voltage, rotation speed, working environment (such as temperature, humidity) and protection level (such as IP65 or higher). You also need to pay attention to the contact material of the slip ring (such as gold-gold, silver-gold) to ensure long-term stable operation.

How long is the life of a 4 Wire Slip Ring?

The life of a 4 Wire Slip Ring is usually more than 10 million rotations, but the actual life depends on factors such as the use environment, load, maintenance, etc. Regular inspection and lubrication can extend its service life.

How to install 4 Wire Slip Ring?

During installation, you need to ensure that the terminals of the slip ring are properly connected to the equipment circuit and that the slip ring fits well with the rotating part. Depending on the model, mechanical mounting or embedded mounting may be required.

Can 4 Wire Slip Ring be used in high temperature environments?

Most 4 Wire Slip Rings have an operating temperature range of -40°C to +80°C. For special high temperature environments, you can choose slip rings with high temperature resistance or custom designs.

Will 4 Wire Slip Ring generate electromagnetic interference?

If improper or poor quality materials are used, 4 Wire Slip Ring may generate electromagnetic interference (EMI). Choosing high-quality slip rings and properly configuring anti-interference shielding materials can reduce this risk.

Is 4 Wire Slip Ring waterproof?

Standard 4 Wire Slip Rings usually have an IP54 protection rating to prevent general dust and water splashes. If higher protection performance is required, models with IP65 or higher protection ratings can be selected.

How does 4 Wire Slip Ring perform in high-frequency signal transmission?

4 Wire Slip Ring is suitable for low to medium frequency signal transmission. If high frequency signal needs to be transmitted, it is recommended to choose a slip ring with a specific design to ensure signal quality and transmission stability.