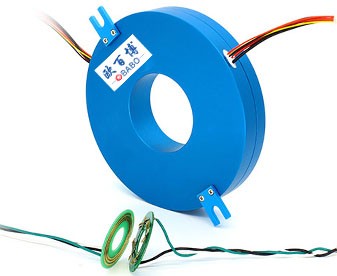

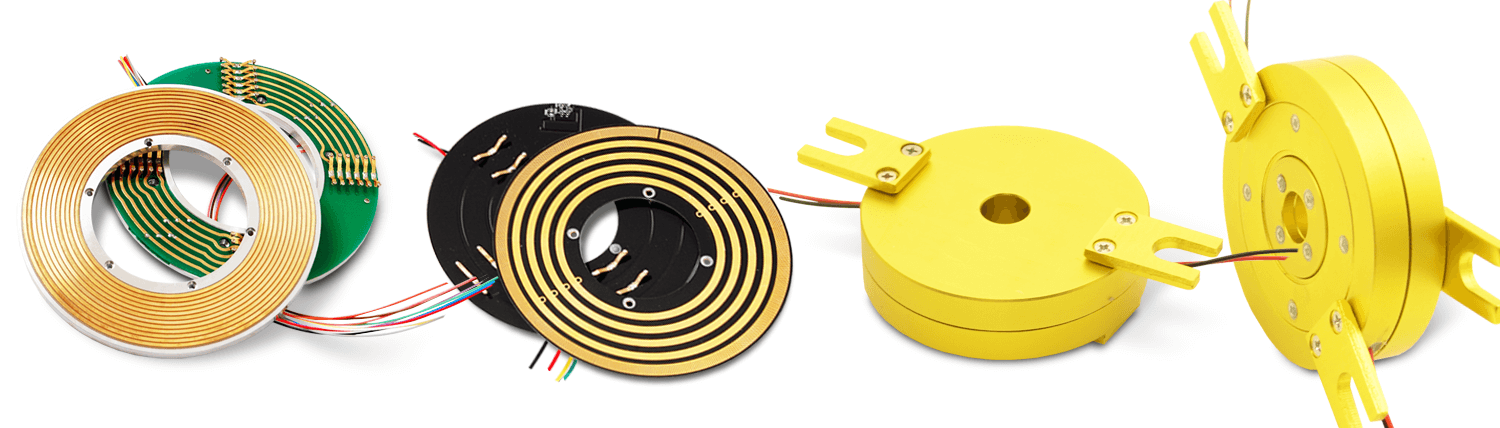

Flat Slip Ring is a highly efficient component for providing power and signal transmission, especially for equipment that requires rotation or high degree of freedom of movement. Unlike traditional round slip rings, Flat Slip Rings use a compact flat design to provide continuous power and signal transmission in a limited space. Flat disc electrical slip rings are widely used in various applications, especially in automation, robotics and precision equipment where space requirements are high.

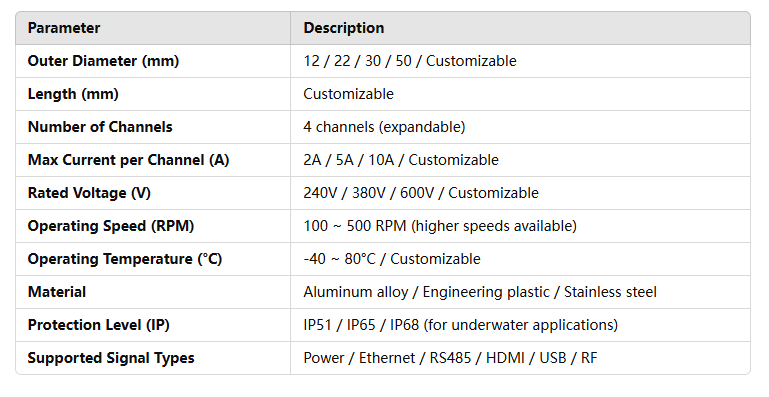

Customers can request customization based on specific application needs. Key customizable parameters include:

Features of Flat Slip Ring

Compact Design

The compact design of Flat Style Slip Ring makes it outstanding in space-constrained equipment, which can effectively save space and adapt to small environments. It integrates multiple signal and power transmission functions, reduces the number of components, and improves system reliability. Low friction and high integration design ensure smooth operation, extend service life, easy installation and integration, suitable for complex systems such as robots and automation equipment.

Multi-function signal support

Flat Style Slip Ring supports multiple signal transmissions, including power, data (such as Ethernet, RS-485), video (HD-SDI, CVI), control signals and sensor data. It can transmit multiple signals simultaneously, simplify system design and improve efficiency. The slip ring provides stable signal transmission and is suitable for complex applications such as robotics, automation, and monitoring equipment, ensuring efficient and reliable operation.

High transmission efficiency

Flat Electrical Slip Ring has low contact resistance, high-frequency signal support, optimized current capacity, and precise signal integration to ensure efficient and stable power and signal transmission. Its low friction and wear-resistant material design prolongs service life, reduces signal attenuation and interference, and improves overall transmission efficiency. It is widely used in automation, robotics, monitoring and other fields to ensure efficient operation of equipment.

Advantages of Flat Slip Ring

Space Saving

The compact design of Flat Slip Ring saves space effectively, especially for space-constrained equipment. Through multi-signal integration, it combines power, data and video transmission channels into one unit, reducing the need for multiple slip rings and simplifying system layout. Its thin structure enables it to operate efficiently in small equipment, robots and automation devices, optimizing space utilization.

High transmission efficiency

Flat Slip Ring achieves efficient power and signal transmission through low contact resistance, high-frequency signal support, optimized current and voltage adaptation, and low-friction material design. It reduces energy loss, extends service life, and ensures stable signal transmission. It is widely used in equipment such as automation, robots and monitoring, providing efficient and reliable performance.

Adapt to complex environments

Flat Slip Ring can work stably in complex environments such as high temperature, low temperature, humidity and corrosion, and adapt to high load and high vibration conditions. It uses high temperature resistant and corrosion-resistant materials and has a dustproof design to ensure long-term reliable operation. Its high stability and low maintenance requirements make it an ideal solution in fields such as industrial automation, aerospace and marine.

Field of use

Automation equipment

In industrial automation, Flat Slip Ring is often used in robots, automated assembly lines, packaging equipment, etc. It can provide stable power and signal transmission to ensure that the equipment is not affected by cable wear during rotation or movement.

Robotics

Robots, especially robotic arms and collaborative robots with multi-degree-of-freedom movement, often require flat slip rings to provide continuous power and signal transmission. Flat slip rings can achieve 360° continuous rotation to meet the requirements of robot motion control, sensor signals and data transmission.

Medical equipment

In medical imaging equipment (such as CT scanners, MRI equipment), flat slip rings are used for power and signal transmission to ensure that the equipment can rotate smoothly while maintaining stable data transmission, supporting high-precision medical operations.

Wind power generation

In wind turbines, flat slip rings are used to transmit power from the stationary part to the rotating part to ensure that the wind turbine can generate power stably, improve power generation efficiency and system reliability.

Aerospace and Military

In aerospace and military equipment, Flat Slip Ring can be used in radar, communication equipment, etc. to support data transmission and power supply, ensuring stable operation of equipment in extreme environments.

FAQ

What to do if the slip ring is overheating?

Overheating of the slip ring is usually caused by excessive current load or poor heat dissipation. The solution is to check the current specifications to ensure that the slip ring can carry the current load. If the current exceeds the maximum load range of the slip ring, a slip ring model suitable for higher current should be selected. In addition, ensure that the slip ring is well ventilated during installation to avoid excessive friction and poor heat dissipation.

What to do if the slip ring makes noise or vibration?

Noise and vibration may be caused by excessive internal friction of the slip ring or improper installation. First, check whether the installation is firm and ensure that the slip ring is well connected to the equipment and not loose. Secondly, check the lubrication status of the slip ring to ensure appropriate lubricating materials to reduce friction and noise. If the problem is still not solved, you can consider replacing a higher quality slip ring or adjusting the load to reduce vibration.

The life of the slip ring is short, how to extend it?

The life of the slip ring is usually related to the use environment, load current and maintenance frequency. To extend the service life, the slip ring should be cleaned regularly to avoid accumulation of dust, oil or other contaminants. Choose a slip ring that is suitable for the working environment and ensure that the slip ring works within the specified load range to avoid overload or overload operation. In addition, using high-quality materials and precision-made slip rings can also help extend their life.

What should I do if the slip ring cannot transmit power or signals normally?

If the slip ring cannot transmit power or signals normally, first check whether the power supply is normal and confirm that the cable and connector are not damaged. Check whether the internal contact of the slip ring is good and whether the contact resistance is too high. If poor contact or damage is found, the slip ring should be cleaned or replaced. If the problem is still not solved, consider checking whether the slip ring is suitable for the current working conditions and replace it with a suitable model if necessary.

How to solve the space problem during installation?

If the slip ring installation space is limited, you can choose a more compact flat slip ring model, which can effectively save installation space and adapt to small environments. The thin design of the flat slip ring makes it perform well in space-constrained equipment and can be installed side by side with other components to maximize the use of space.