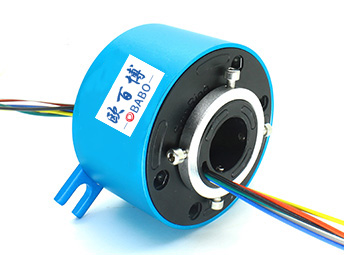

USB 3.0 slip ring is a rotating connector designed for transmitting data and power signals. It allows USB 3.0 signals to be continuously transmitted through rotating parts. The role of the slip ring is to stably transmit USB 3.0 data and power when the device needs to rotate. Such Slip rings are widely used in rotating systems that require data transmission and power supply, such as robots, rotating displays, antenna systems, turntables, etc.

| Parameter | Description | Notes |

|---|---|---|

| Data Transmission Speed | Supports USB 3.0 standard, up to 5Gbps | Can be customized to support USB 2.0, 1.1, etc. |

| Voltage | 5V DC (Standard USB 3.0 requirement) | Can be customized for higher voltage requirements |

| Current | Up to 1.5A (Standard USB 3.0 requirement) | Can be customized for higher current needs |

| Durability/Rotation Life | Minimum 5 million rotations | Can be customized as per customer requirements |

| Materials | High-quality copper or other conductive materials | Different materials can be chosen based on environmental needs |

| Enclosure Protection Rating | IP52, IP65, IP67, etc. | Protection ratings can be customized per customer needs |

| Operating Temperature Range | -20°C to 60°C | Can be customized for wider temperature ranges |

| Size | Customized based on device requirements | Suitable for compact or large designs |

| Mounting Method | Flange mount, axial mount, embedded mount, etc. | Customizable mounting methods based on customer needs |

| Signal Integrity | Shielded design to ensure data integrity | Shielding levels can be customized |

| Rotation Speed | Supports high-speed rotation, up to 300 RPM | Can be optimized per customer needs |

| Number of Channels Supported | Single channel or multi-channel (e.g., USB 2.0, USB 3.0, data/power) | Multi-channel designs available per requirements |

Operating principle

The basic operating principle of USB 3.0 slip rings is to establish an electrical connection through a set of annular electrical contacts and brushes to maintain the transmission of power and data. When the inner and outer components of the slip ring rotate, the electrical contacts will continuously rub and transmit signals to maintain stable electrical contact. These slip rings are usually made of high-precision materials to ensure the quality and reliability of the signal.

Data transmission speed

USB 3.0 has a transmission speed of up to 5Gbps, which greatly improves the data transmission rate compared to USB 2.0 (maximum 480Mbps). This makes USB 3.0 slip rings important in applications that require high bandwidth (such as high-definition video transmission, high-speed data acquisition, cloud computing, etc.).

Signal integrity

Signal integrity refers to whether the signal is distorted due to electromagnetic interference (EMI), signal attenuation and other issues during data transmission. USB 3.0 slip rings usually use high-quality conductive materials and are designed with good shielding functions to reduce interference and maintain high-quality signal transmission. In addition, the contact point design in the slip ring must ensure that there is no signal loss or attenuation during rotation.

Current and voltage requirements

The USB 3.0 standard requires a 5V voltage and supports a current of up to 1.5A. For devices that require more power support, special customization may be required to provide higher current. The power channel in the slip ring needs to meet these standards to ensure that stable voltage and current can be provided to avoid device function limitations due to insufficient power.

Advantages

High-speed data transmission

USB 3.0 slip rings support high-speed full-duplex data transmission up to 5Gbps, with stable signals, low latency, strong EMI shielding, hot plug and multi-protocol compatibility, suitable for video, image, and control signal transmission in high-speed rotation scenarios.

Stability

USB 3.0 slip rings have excellent stability, using highly conductive materials and precision structural design to ensure continuous and stable connection during rotation; combined with EMI shielding and differential transmission, signal interference is effectively avoided, and it is suitable for high-frequency, high-speed, and high-reliability data transmission scenarios.

High durability

USB 3.0 slip rings have high durability, use wear-resistant materials and high-life design, support millions of rotations, have dust, shock, and moisture resistance, are suitable for long-term operation and harsh environments, and ensure stable operation in high-reliability scenarios such as industry and medical care.

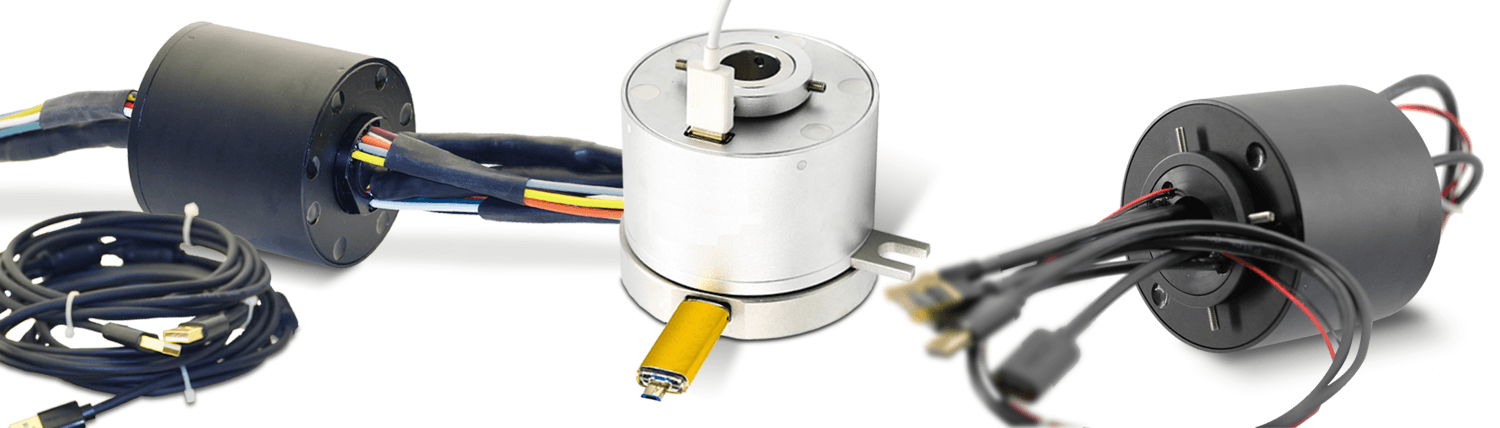

High compatibility

USB 3.0 slip rings are highly compatible, support backward compatibility with USB 2.0/1.1, and are compatible with multiple types of USB devices; they can be integrated with HDMI, Ethernet, RS485 and other signal and power channels to meet the needs of multi-interface systems and are suitable for a variety of industrial, automation and intelligent device scenarios.

Scope of use

USB 3.0 slip rings are widely used in many fields, especially those that require high data transmission speed and stability while also requiring rotation functions. Common applications include:

Robotic systems: Robot joints or turntables require data transmission during rotation.

Rotating cameras: Surveillance cameras for 360-degree rotation require real-time transmission of video data.

Antenna systems: Rotating antennas for satellite communications or broadcasting.

Medical equipment: such as rotating CT scans, X-ray equipment, etc.

Industrial automation: used in industrial control systems that require rotation and real-time data transmission.

FAQ

What is a USB 3.0 slip ring and what does it do?

A USB 3.0 slip ring is a device that allows data and power to be transmitted over a rotating connection. It is mainly used in scenarios that require rotation or rotation to maintain the high-speed data transmission and power transmission of USB 3.0. Slip rings ensure that the connection is not disconnected by transmitting signals between the rotating part and the fixed part, and are commonly found in robots, rotating devices or automated equipment.

What are the most common problems when using USB 3.0 slip rings?

The most common problems include:

Signal interference or loss: Poor contact of the rotating part or quality problems of the slip ring may cause data transmission interruption.

Current loss or insufficient power supply: Failure of the power transmission part of the slip ring causes insufficient power supply to the device.

Unsmooth rotation: Wear or insufficient lubrication of the mechanical part of the slip ring may cause unsmooth rotation, affecting the user experience.

Overheating problem: Long-term operation or excessive current may cause the slip ring to overheat and damage internal components.

Physical damage: Frequent mechanical vibration or excessive rotation may cause damage to the outer shell or internal components of the slip ring.

How to solve the signal interference or loss problem of USB 3.0 slip ring?

Ways to solve signal interference or loss include:

Check whether the slip ring connection line and interface are firm and make sure there is no looseness.

Use high-quality slip rings to avoid poor contact caused by low-quality products.

Make sure that the installation environment of the slip ring does not have excessive electromagnetic interference.

Maintain and clean the slip ring to avoid dust or dirt affecting signal transmission.

How to solve the problem of insufficient power supply of USB 3.0 slip ring?

Ways to solve insufficient power supply include:

Check whether the power supply access of the slip ring is normal and ensure that the power supply is stable.

Use slip rings with higher power carrying capacity to avoid overload.

Check the power line regularly to avoid breakage or wear.

If the device requires high current, consider upgrading the slip ring or using an external power supply.

How to prevent USB 3.0 slip rings from overheating?

Ways to prevent overheating include:

Make sure that the slip ring has adequate ventilation when working and avoid using it in a confined space.

Avoid running the slip ring for a long time, especially when it is under high power load.

Regularly check the operating status of the slip ring, especially in high-load environments, to detect signs of overheating in time.

What to do if the rotation is not smooth?

The solution to the problem of smooth rotation includes:

Check whether the slip ring needs lubrication and use a suitable lubricant to reduce friction.

Clean the slip ring regularly to avoid dust and dirt accumulation affecting the rotation.

Check whether there is wear on the mechanical parts and replace the worn parts if necessary.

How to extend the service life of USB 3.0 slip rings

Ways to extend the service life include:

Regularly check the connection part of the slip ring to ensure that it is not loose or damaged.

Avoid overloading the slip ring and ensure that the operating current and load are within the load range of the slip ring.

Clean and lubricate the rotating part of the slip ring regularly.

Use protective devices such as dust covers to prevent damage to the slip ring from the external environment.