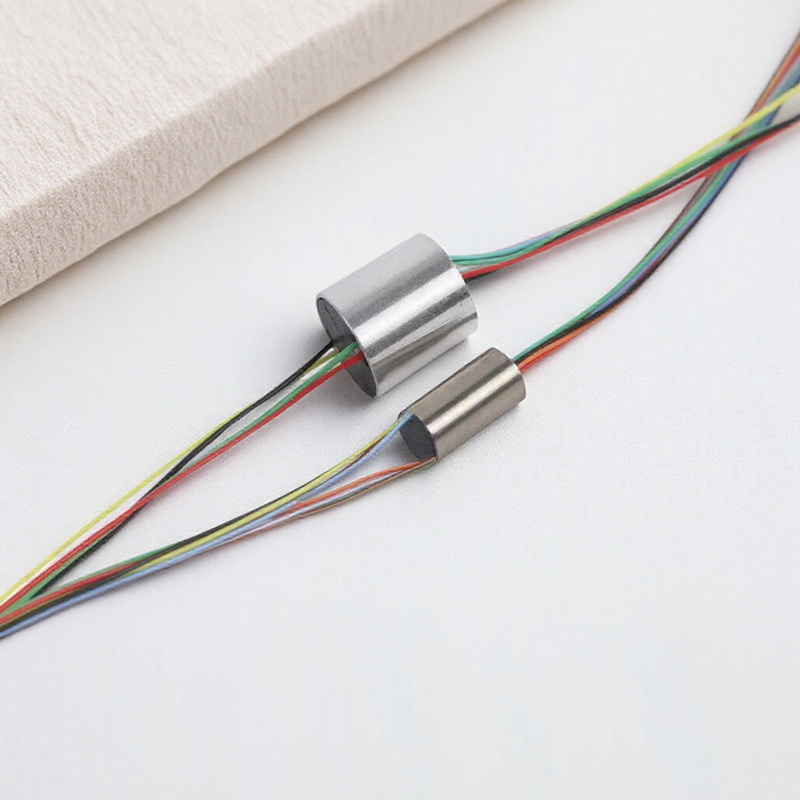

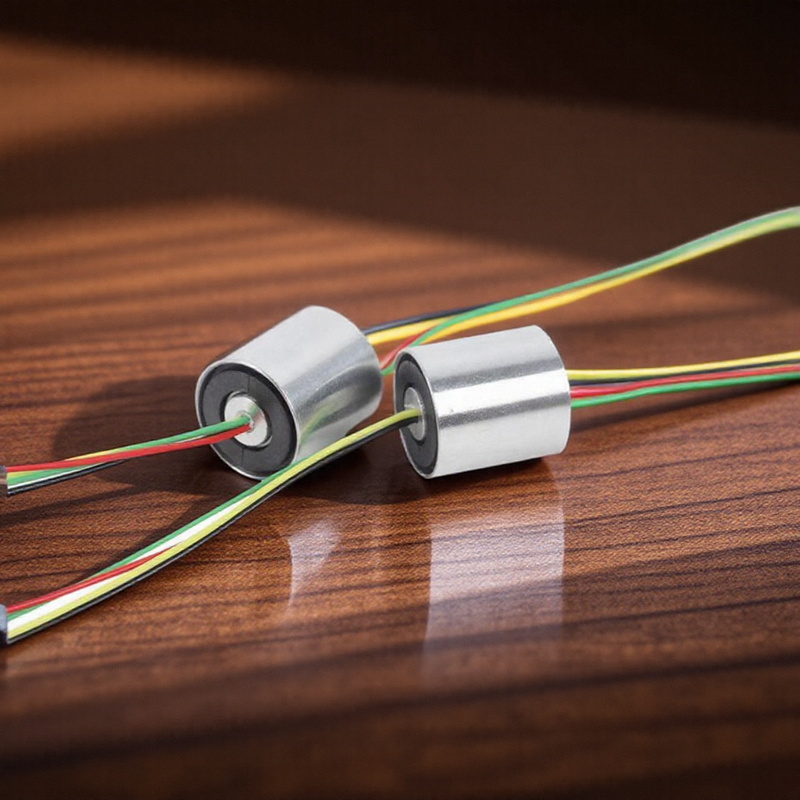

Ultra Micro Small Conductive Slip Ring is a key component for electrical transmission, especially for systems that require continuous rotation and stability of signal transmission. It is mainly used in machines, industrial equipment, robots and other applications that require power or data transmission and require rotational freedom.

Working Principle

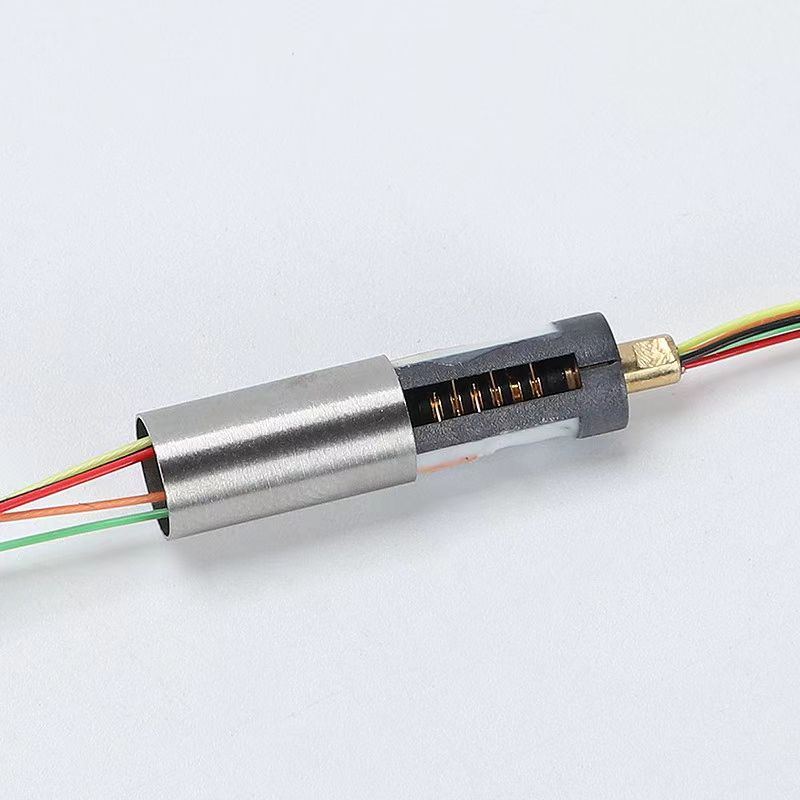

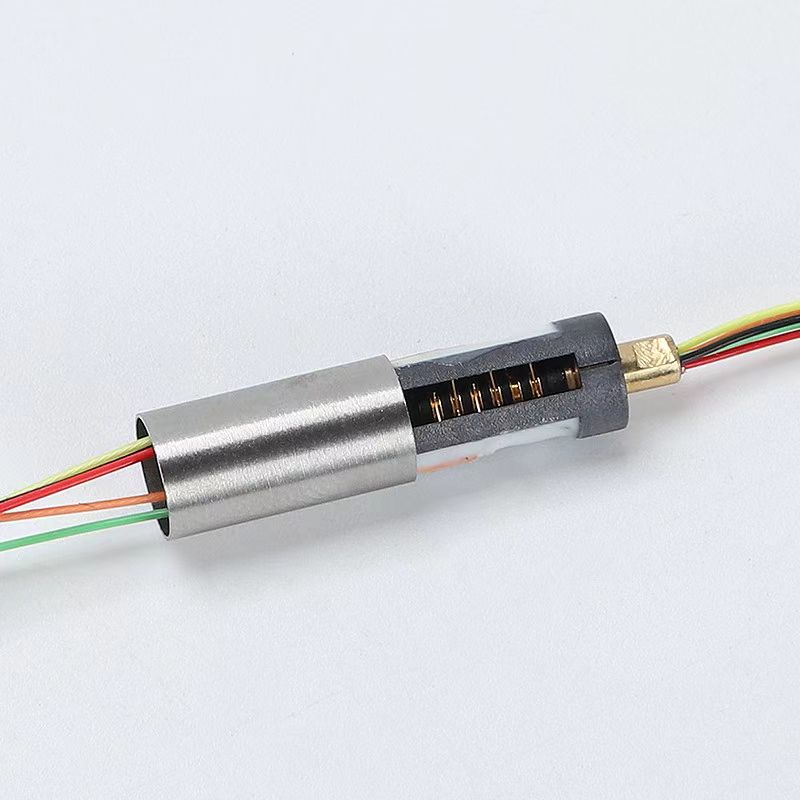

Ultra Micro Small Conductive Slip Ring achieves seamless transmission of current or signal in rotational motion through contact between conductive brushes and annular conductors. Slip Ring is essentially a mechanical component that can maintain stable transmission of current or signal during rotation without being restricted by cables. Slip rings are composed of multiple annular electrical conductors, and brushes contact these conductors to achieve signal or current transmission.

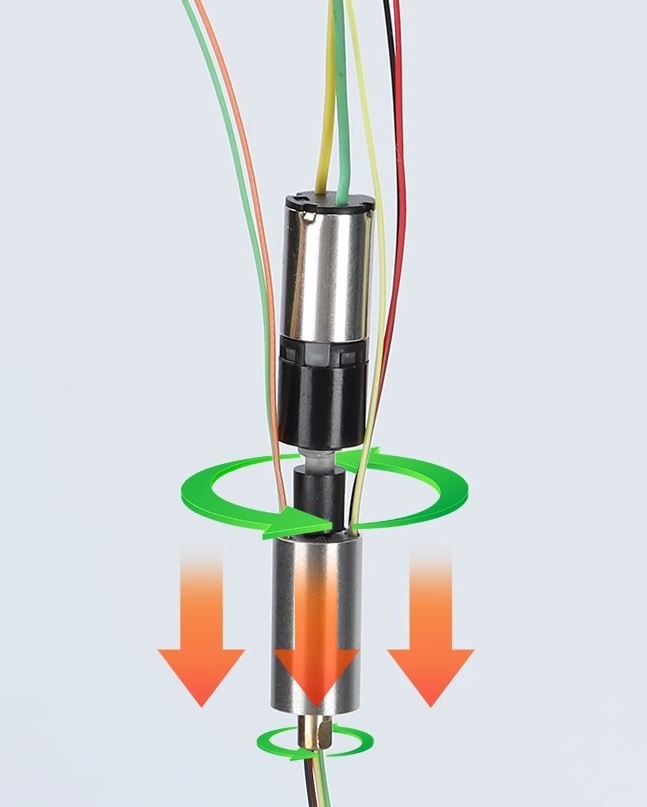

Coupling drives slip ring rotation

slip ring is connected to motor or other rotating mechanical parts through coupling, and coupling transmits power to slip ring, so that it transmits current or signal during rotation.

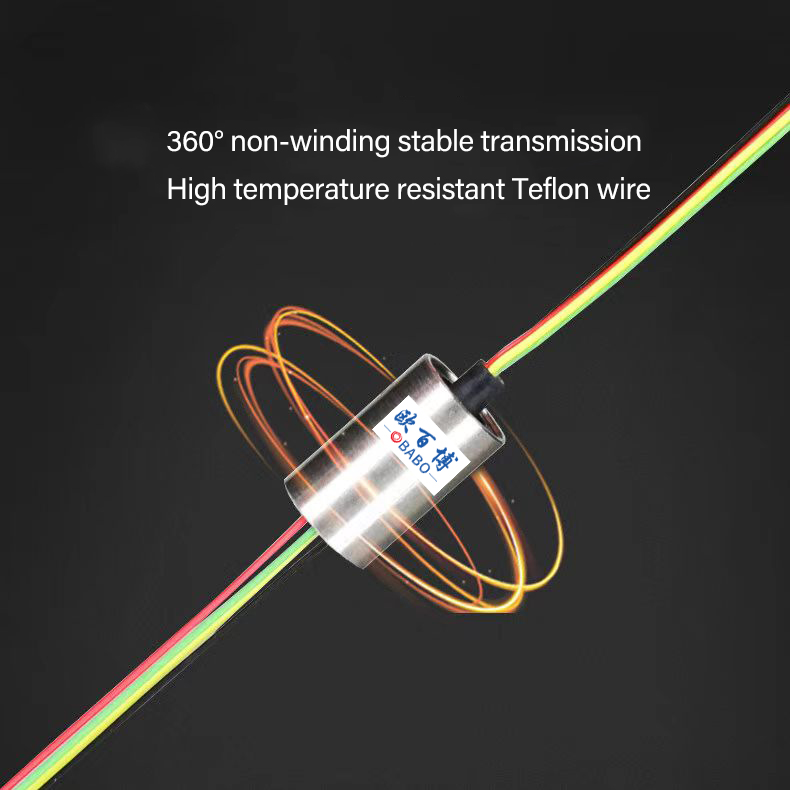

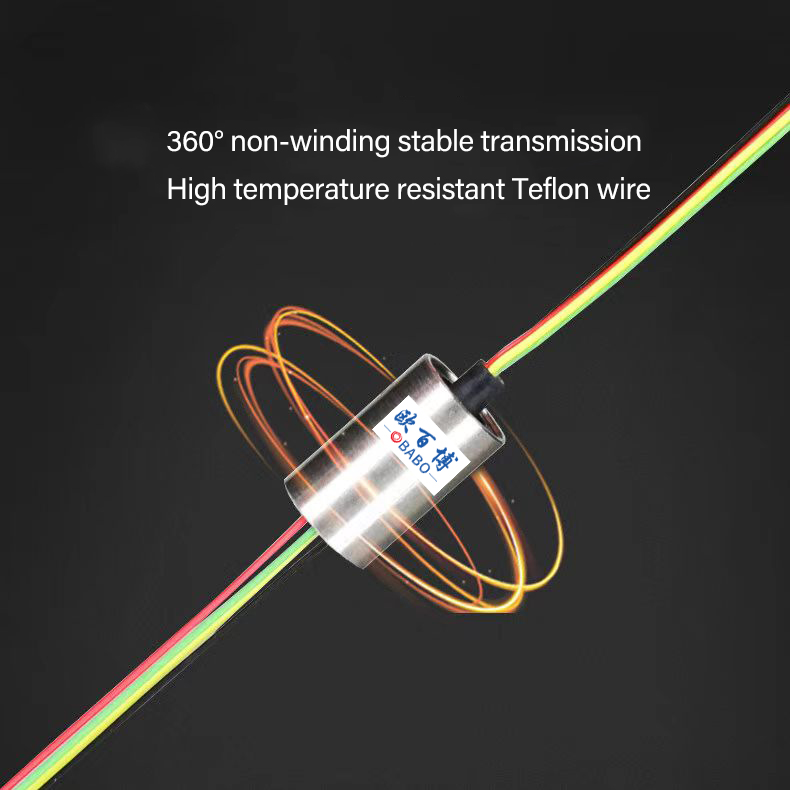

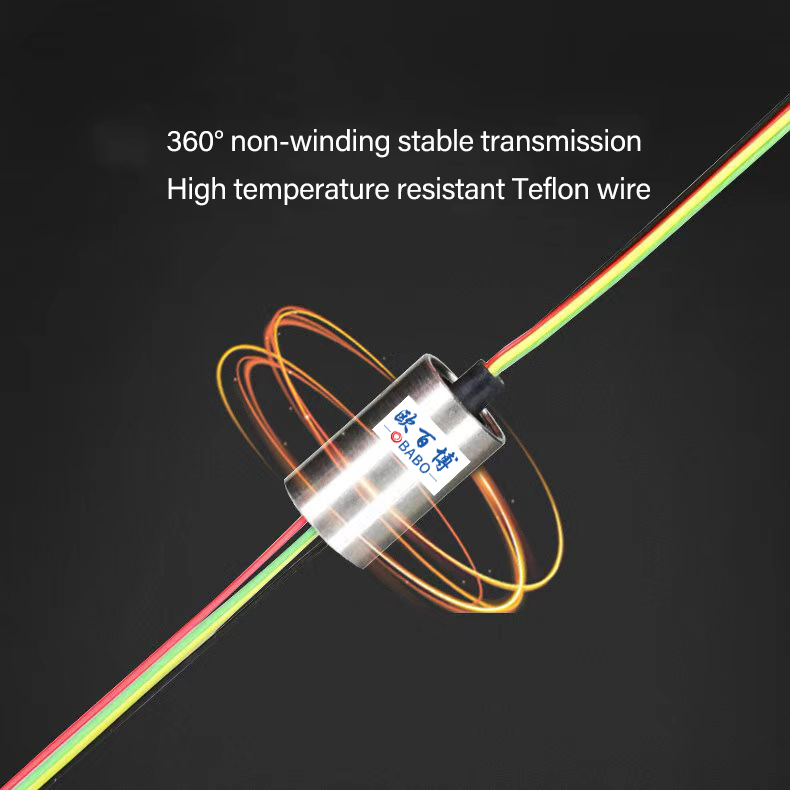

360° non-winding stable transmission

through the slip ring structure, it can be ensured that the cable does not have winding problems, and the slip ring will not cause wire damage or transmission interruption when rotating.

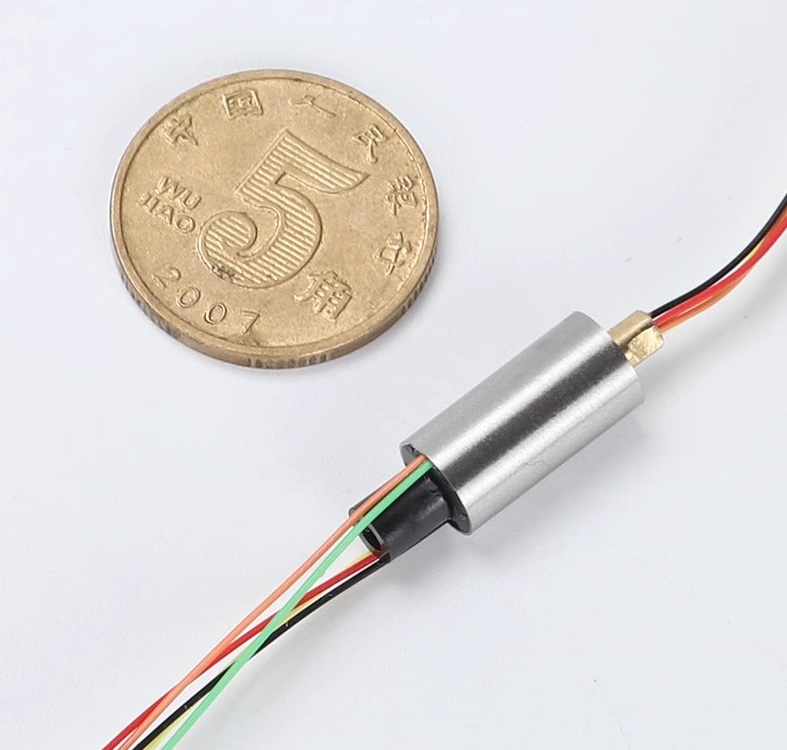

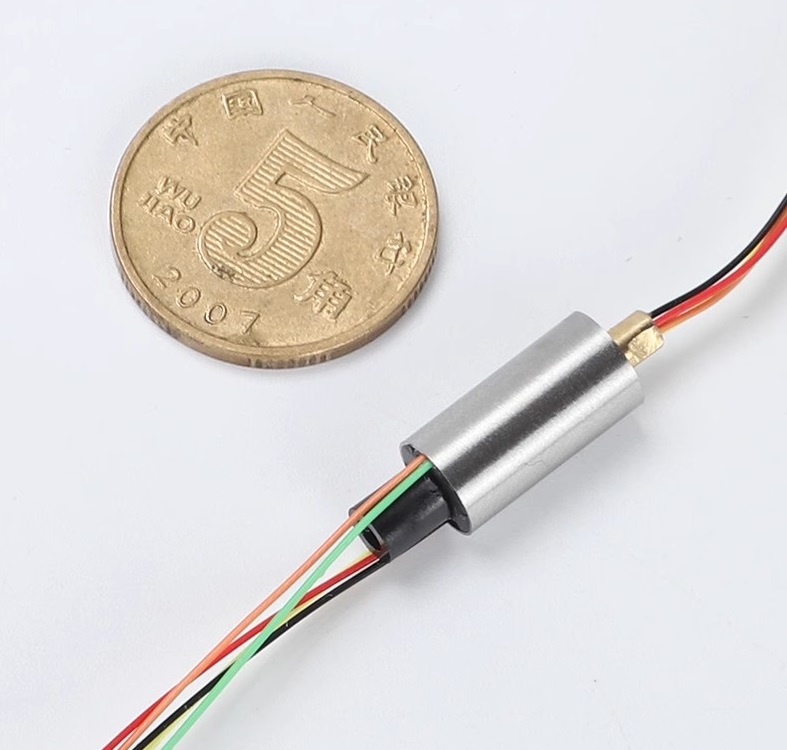

Small size and high precision

The micro design makes it suitable for applications with limited space, and precision manufacturing ensures the stability and high precision of signal transmission.

Signal stability is applicable to industrial fields

The slip ring design pays special attention to the application in industrial environment, which can effectively avoid the influence of factors such as high temperature, high humidity and vibration.

Not easy to heat

Slip rings usually use highly conductive materials, which can reduce contact resistance and avoid excessive heating.

Long service life

High-quality materials and precision manufacturing make the slip ring have a long service life and can withstand long-term and high-frequency use.

Silver-plated colored wire, strong conductivity

Silver-plated wire can effectively improve conductivity, reduce signal loss, and has good corrosion resistance.

Material

Slip Ring Body Material

Ultra Micro Small Conductive Slip Ring generally uses materials such as high-conductivity copper and metal alloys, which have excellent electrical conductivity and durability.

Brush Material

The brush of Ultra Micro Small Conductive Slip Ring uses materials such as carbon brushes or silver brushes, which have low resistance and can adapt to high-frequency wear.

Wire Material

Ultra Micro Small Conductive Slip Ring uses silver-plated copper wire, which has excellent conductivity and corrosion resistance and can provide stable signal transmission.

Advantages

Smooth operation: Due to the precise structure of the slip ring and the good contact between the brush and the conductor, the signal transmission process is very smooth during the rotation process.

Small resistance fluctuation: High-quality materials and design ensure the stability of resistance, avoid fluctuations in current transmission, and ensure high stability.

Long life: Using high-quality materials and precise manufacturing processes, the slip ring has a long service life and reduces maintenance costs.

Low torque: The design of the slip ring minimizes friction during rotation, which helps to reduce the burden on the drive system and improve the overall efficiency of the system.

Scope of use

Robots: In industrial robots that need to rotate 360 degrees, conductive slip rings can maintain the transmission of current and signals.

Medical equipment: Such as rotating X-ray machines or MRI scanners, slip rings ensure that the signal and current are uninterrupted when the equipment rotates.

Automated production lines: Slip rings can be used to transmit signals and power, and are suitable for control systems of automated equipment.

Wind power generation: The rotating part of the wind turbine needs to transmit power through slip rings.

Aerospace: Slip rings play a key role in rotating devices that require high-precision signal transmission.

Camera equipment: Such as rotating cameras or pan-tilt heads, signal transmission needs to be kept uninterrupted.

Maintenance and maintenance

Regular inspection: Regularly check the wear of the conductive brush to ensure that it has good contact with the slip ring. If the wear is severe, the brush needs to be replaced in time.

Cleaning: The surface of the slip ring and brush is prone to dust accumulation. Regular cleaning of the slip ring and conductive brush can reduce poor contact or signal interference.

Avoid overload: Ensure that the use of the slip ring does not exceed the rated power and load to extend the service life.

Check contact resistance: Check the stability of contact resistance regularly. Too high resistance may cause signal loss or heating.

Lubrication: Some slip rings may need regular lubrication to reduce friction and keep them running smoothly.

Through these maintenance measures, the service life of the slip ring can be effectively extended and its excellent working performance can be maintained.

FAQ

What are the common faults of conductive slip rings?

Common faults of conductive slip rings include:

Poor contact: Poor contact between the brush and the slip ring may cause signal loss or power transmission interruption.

Excessive wear: Wear of the brush or slip ring will affect the transmission effect and need to be replaced in time.

Overheating: Excessive current or high contact resistance may cause the slip ring to heat up and affect the service life.

How to maintain the conductive slip ring?

The maintenance of the conductive slip ring includes:

Regular inspection: Check the wear of the brush and slip ring, and replace the brush if necessary.

Cleaning: Clean the surface of the slip ring regularly to remove dust or contaminants and maintain good contact.

Check the contact resistance: Make sure the resistance remains within the normal range to avoid signal loss.

Avoid overload: Do not exceed the rated power of the slip ring during use to avoid overload damage to the equipment.

Lubrication: If necessary, lubricate the slip ring regularly to reduce friction and improve stability.

How high a speed can the conductive slip ring withstand?

The speed tolerance of the conductive slip ring depends on the specific design and material. Generally speaking, standard industrial slip rings can withstand several thousand revolutions per minute (RPM), while high-precision or customized slip rings may adapt to higher speeds. Specific requirements should be selected according to the actual application.

Why does the resistance fluctuation of the slip ring be small?

The small resistance fluctuation of the slip ring is mainly due to high-quality conductive materials (such as silver brushes and silver-plated wires) and precise manufacturing processes. These designs ensure stable contact between the brush and the slip ring body, reduce resistance fluctuations caused by friction and poor contact, and ensure the stability of signal and current transmission.