2025-04-19 11:26:16

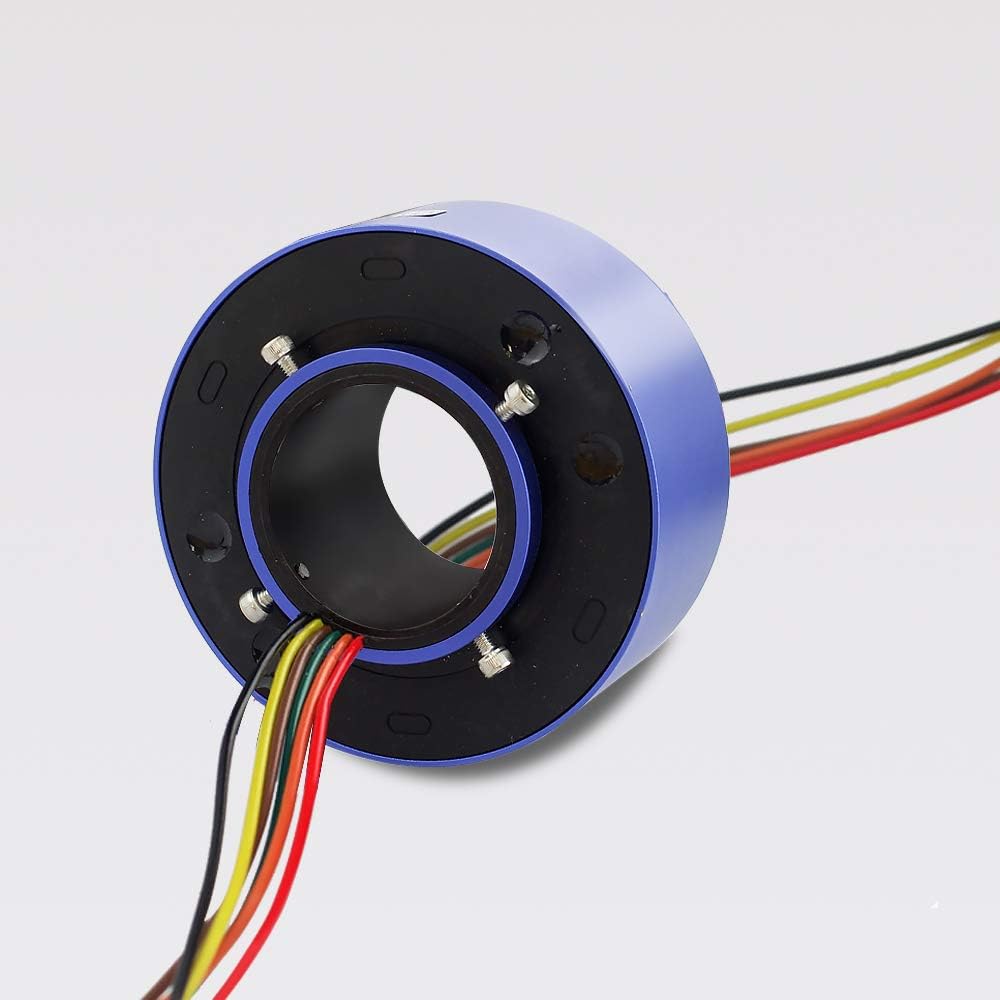

What is Conductive Slip Ring?

Conductive Slip Ring is an electrical connection device that allows current to be transmitted between a rotating object and a fixed object. Through this device, continuous transmission of electrical signals or power in rotating devices can be achieved, and it is widely used in machines and equipment that need to rotate or turn. Conductive Slip Rings usually consist of a set of brushes (or brushes) and contact rings, and the contact between the brushes and the rings realizes current transmission.

Features:

Continuous transmission of current: Conductive Slip Rings can continuously transmit current or signals when the object rotates. Suitable for systems that require 360-degree rotation.

Multi-channel design: Most conductive slip rings can be designed as multi-channels, supporting the simultaneous transmission of multiple signals and power, such as power, data, video, etc.

Wear resistance and long life: The contact rings and brushes are made of high-quality conductive materials (such as gold, silver, copper, etc.) to ensure low wear and long service life.

Uninterrupted electrical connection: No matter how the equipment rotates, the conductive slip ring can ensure uninterrupted transmission of electrical signals, avoiding the wear problem of traditional winding cables.

Compact and efficient design:

Modern conductive slip ring designs tend to be miniaturized and suitable for applications with limited space.

Low noise and stability:

High-quality conductive slip rings have low electrical noise, ensuring stable signal transmission.

Advantages

Improve equipment performance:

In mechanical equipment that requires continuous rotation, conductive slip rings can effectively provide power and signal transmission, allowing the equipment to operate smoothly for a long time.

Reduce wear and maintenance costs:

Compared with traditional cables and connections, the design of conductive slip rings reduces wear, reduces the need for frequent cable replacement, and reduces maintenance costs.

High reliability:

Due to their simple structure and durability, conductive slip rings can usually provide long-term stable electrical connections and are suitable for use in demanding industrial environments.

Adapt to high-speed applications:

Suitable for use in high-speed rotation applications, supporting high-frequency rotation without signal loss or current interruption.

Multiple application scenarios:

Can be designed as a multi-channel version to meet different system requirements and support multiple transmission methods such as power, signal, and video.

Scope of application

Robotics:

In industrial robots, conductive slip rings ensure the transmission of control signals and power between rotating parts such as robotic arms.

Wind power generation:

In wind turbines, conductive slip rings are used to transmit rotating electrical energy to fixed control systems.

Marine equipment:

Such as offshore drilling platforms, conductive slip rings can be used to transmit power or data to ensure the stable operation of deep-sea equipment.

Automated production lines:

Used in automated production equipment to ensure the electrical connection between rotating equipment and fixed equipment, especially in automated robotic arms or transmission systems.

Sensor applications:

In sensor systems that require 360-degree rotation, conductive slip rings ensure that the data transmission of sensors is not disconnected.

Aerospace

In rotating parts of aircraft or spacecraft, conductive slip rings are used to transmit power and signals to keep the communication system stable.

CCTV and monitoring systems:

Used in monitoring cameras to ensure stable transmission of video signals.

Automobile and motorcycle applications:

In the rotating systems of automobiles, such as steering wheel controls or wheel position sensors, conductive slip rings can stabilize power and signal transmission.

Precautions for use:

Avoid overload:

When selecting a conductive slip ring, ensure that the current and voltage it bears meet the requirements of the actual application, and avoid overload operation and damage.

Regular inspection and maintenance:

Although the design life of the conductive slip ring is long, it is also necessary to regularly check the wear of the brush and contact ring. If excessive wear is found, it needs to be replaced in time to keep the equipment running stably.

Prevent corrosion:

When used in harsh environments (such as humid or highly corrosive environments), choose slip rings with corrosion resistance to avoid affecting the stability of electrical connections due to corrosion.

Proper installation and adjustment:

When installing the conductive slip ring, ensure its axial alignment and ensure good contact between the brush and the contact ring. Adjust the pressure of the brush to avoid excessive pressure causing excessive wear.

Avoid severe vibration:

During use, try to avoid severe vibration or impact, as this may cause the internal components of the slip ring to loosen or damage.

Choose suitable conductive materials:

Choose suitable conductive materials according to different application scenarios. For example, for applications with high temperature, high speed or special environment, metal materials with high temperature resistance and wear resistance (such as gold or silver alloy) should be selected.

Avoid overspeed operation:

Most conductive slip rings have a specified speed limit. Exceeding this speed may cause increased wear of the brush and contact ring, or even electrical failure.

FAQ

Why does my conductive slip ring have signal loss or unstable transmission?

Signal loss or unstable transmission is usually due to the following reasons:

Excessive brush wear: Poor contact between the brush and the contact ring will cause unstable signals. Check the brushes regularly and replace the severely worn parts in time.

Improper installation: If the conductive slip ring is not installed correctly, it may cause poor contact between the brush and the contact ring, which will affect signal transmission.

Overload or overload use: Current or voltage beyond the design load range may cause poor contact or even equipment damage.

Pollution or corrosion: Dust, moisture or corrosive substances in the environment may affect the normal operation of the conductive slip ring. Make sure the equipment operates in a clean and dry environment.

How long is the life of the conductive slip ring? How to extend its service life?

The life of the conductive slip ring depends on its use conditions, load, speed and other factors. Generally, a good conductive slip ring can be used for thousands of hours or even longer. Measures to extend the life include:

Regular inspection: Check the wear of the brushes and contact rings and replace them in time.

Appropriate load: Avoid overload operation, especially in current and speed.

Avoid humid environment: Make sure the conductive slip ring is in a dry environment to prevent moisture and corrosion from damaging it.

Cleaning and maintenance: Clean the contact ring and brush regularly to remove dust and dirt and maintain good contact.

How to choose the right conductive slip ring?

When choosing the right conductive slip ring, you need to consider the following factors:

Current and voltage requirements: Make sure the rated current and voltage of the slip ring can meet the needs of the application.

Speed range: Select the appropriate slip ring model according to the speed of the equipment to avoid overspeed operation.

Number of channels: If you need to transmit multiple signals (such as power, data, video, etc.), choose a multi-channel slip ring.

Environmental conditions: Choose materials that adapt to temperature, humidity and corrosiveness according to the application environment.

Installation space: Choose a conductive slip ring of the right size according to the size of the equipment and the installation space.

My conductive slip ring has an overheating problem, what should I do?

Overheating of the conductive slip ring may be caused by the following reasons:

Excessive current: The load exceeds the design current range during use, resulting in overheating. Check whether the current load is within the rated range of the slip ring.

Excessive friction: Excessive friction between the brush and the contact ring may cause overheating. Check the pressure of the brush to ensure it is appropriate and avoid excessive wear.

Excessive ambient temperature: If the working environment temperature is too high, it may cause poor heat dissipation of the equipment and overheat. Try to keep the equipment at a suitable operating temperature.

Poor heat dissipation: Check whether the heat dissipation design of the conductive slip ring is reasonable and ensure that it has enough space for heat dissipation.

What types of equipment are conductive slip rings suitable for?

Conductive slip rings are suitable for a variety of equipment that requires rotation and electrical connection. Common applications include:

Robotic systems: used to transmit control signals and power.

Wind turbines: Transmit power from the rotating part to the fixed part.

Surveillance cameras: Used to transmit video signals to ensure that the camera signal is continuous when rotating.

Automation equipment: such as rotating equipment on the production line.

Aerospace and military equipment: such as radar systems, satellite antennas, and other applications that require continuous rotation and transmission of signals and power.

Why do my conductive slip rings have brushes that wear too quickly?

Brushes may wear too fast for several reasons:

Excessive brush pressure: Excessive pressure will increase the friction between the brush and the contact ring, which will accelerate wear. Adjust the brush pressure to maintain proper contact force.

Inappropriate material selection: Mismatched materials between the brush and the contact ring may cause excessive wear. Select the appropriate brush and contact ring materials according to the conditions of use.

Abnormal speed or load: Overspeed or overload operation will cause increased brush wear. It is recommended to operate within the designed load and speed range.

Poor installation or alignment issues: Uneven wear will also occur if the slip ring is installed unbalanced or the brush and contact ring are not aligned correctly.

How to avoid electrical noise in the use of conductive slip rings?

Electrical noise is usually caused by poor contact or interference between the brush and the contact ring. To reduce noise, the following measures can be taken:

Choose high-quality materials: Use low-impedance conductive materials (such as gold, silver alloys, etc.) to reduce noise.

Regular cleaning: Clean the brushes and contact rings regularly to prevent dust and dirt from affecting electrical contact.

Proper contact pressure: Adjust the contact pressure of the brush to avoid too high or too low to ensure a stable electrical connection.

Use filters: If the noise problem is serious, signal interference can be reduced by adding electrical filters.

Can conductive slip rings work in harsh environments?

The environmental resistance of conductive slip rings depends on their design and materials. For harsh environments (such as high temperature, high humidity, corrosive environments, etc.), special materials and designs can be selected, such as:

Anti-corrosion design: Corrosion-resistant materials (such as stainless steel, metal alloys, etc.) are selected to manufacture slip rings and brushes.

Dustproof and waterproof design: Ensure that the equipment has an appropriate dustproof and waterproof rating (such as IP67, etc.) to cope with humid or dusty environments.

High temperature resistant materials: For high temperature environments, choose slip rings and brush materials that are resistant to high temperatures.

When using conductive slip rings, the problems encountered usually involve brush wear, signal loss, overheating, etc. Most of these problems can be avoided through reasonable selection, regular maintenance, and ensuring the appropriateness of the use environment. Through proper installation, regular inspection and maintenance, the service life of the slip ring can be extended and the stable operation of the equipment can be ensured.