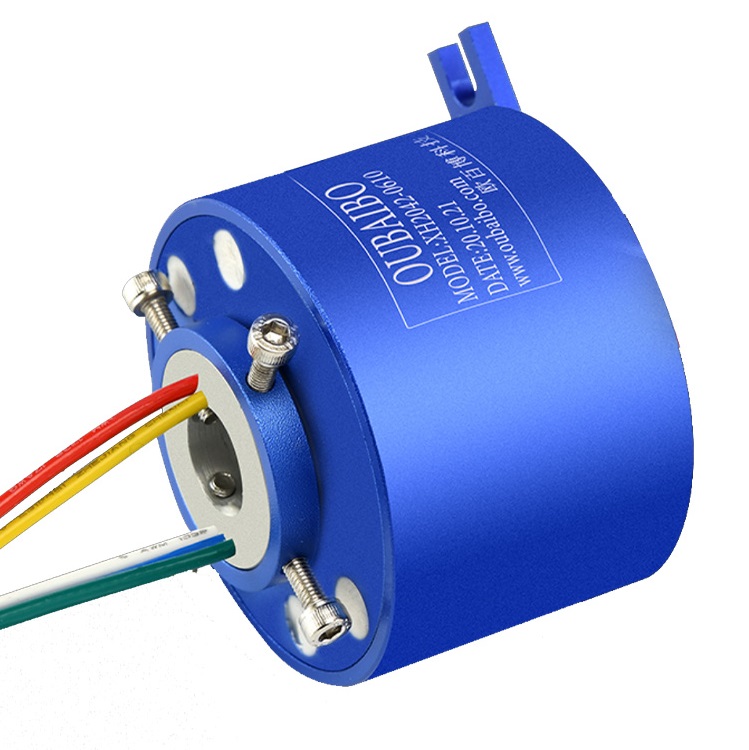

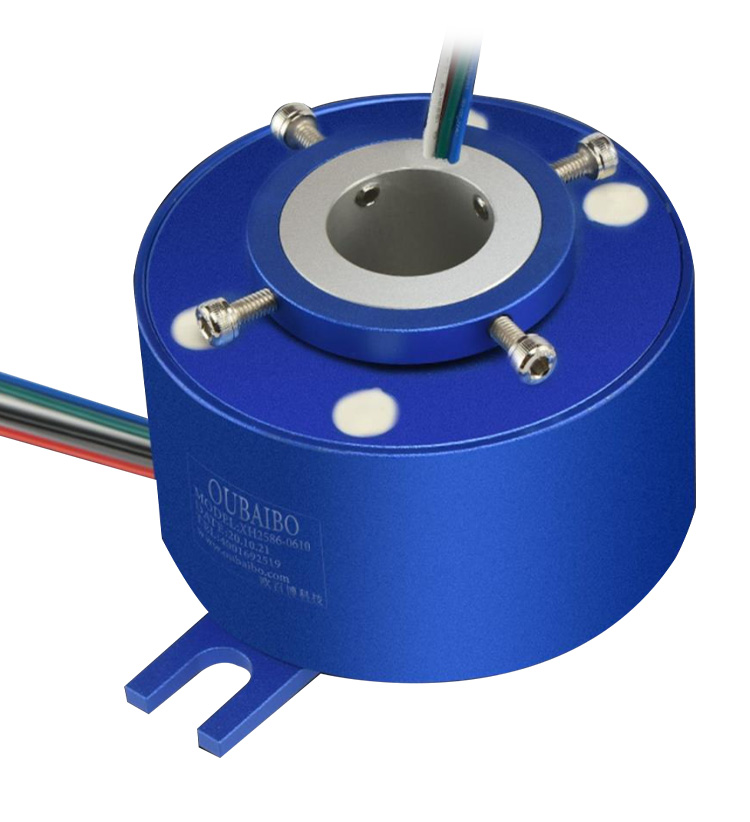

Through-hole rotary joint – 360° continuous rotation, high speed and high current

Multi Passage Rotary Union is a precision engineering component used to transmit power, signal, gas or liquid between fixed and rotating parts. The 360° continuous rotation capability of the Through Bore Rotary Union can be combined with the center through-hole structure to allow the shaft, tube or cable to pass through the middle, which is particularly suitable for a variety of complex working conditions such as hydraulic, electric and pneumatic systems.

Operation Principle

Multi Passage Rotary Union uses the central through-hole structure to pass the internal cables and pipes, and relies on the conductive slip rings and brushes between the stator and the rotor to transmit electrical signals or currents. The rotating part is supported by high-precision bearings to maintain low friction and stable operation. The multi-channel independent design can simultaneously transmit electricity, gas, liquid and other media, realizing 360° continuous rotation of the equipment without interruption, and is widely used in automation, robots, and high-temperature equipment.

Technical Specifications

| Parameter | Value | Parameter | Value | Parameter | Value |

|---|---|---|---|---|---|

| Service Life | Customization | Rated Voltage | 0~240VAC/VDC | Power | 0~240VAC/VDC |

| Rated Speed | Customization | Insulation Resistance | ≥500MΩ/500VDC | Signal | ≥500MΩ/500VDC |

| Operating Temperature | -30°C~80°C | Wire Specification | AWG26# Tinned Copper PTFE | Wire Spec | AWG26# Tinned Copper PTFE |

| Operating Humidity | 0~85%RH | Wire Length | Standard length 300mm (adjustable upon request) | ||

| Contact Material | Customization | Dielectric Strength | 500VAC@50Hz, 60s | ||

| Housing Material | Aluminum Alloy | ||||

| Rotational Torque | 0.05N.m ± 0.02N.m / 6 circuits | Dynamic Electrical Noise | <0.01ω<> | ||

| Protection Grade | IP51 |

Material Selection and Processing

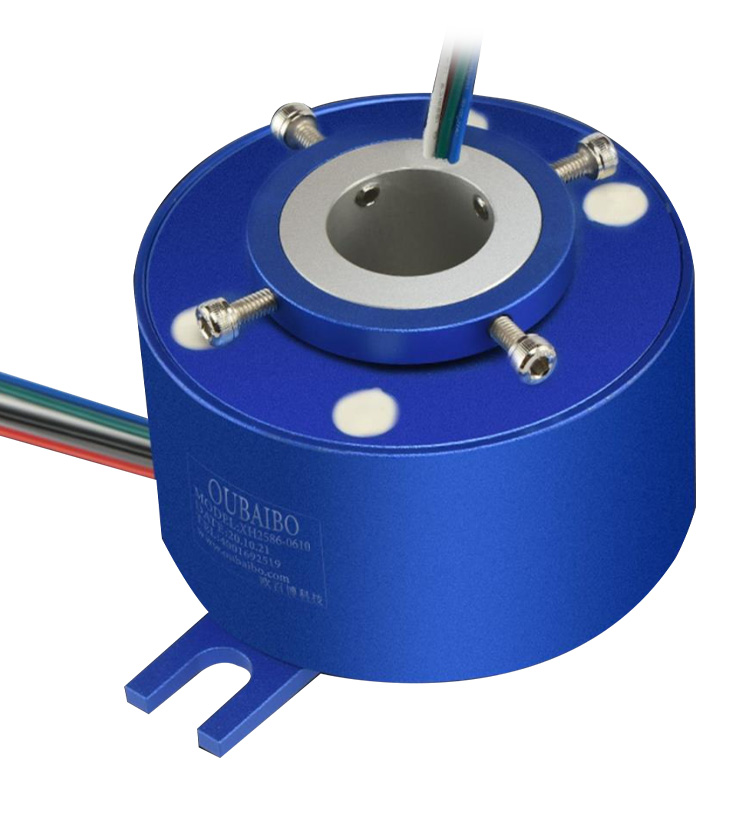

High-quality aluminum alloy shell

It is an important material for Multi Passage Rotary Union . It is light and strong, and is very suitable for dynamic parts. Aluminum alloy can not only effectively dissipate heat, but also has good corrosion resistance. After anodizing, the surface hardness and wear resistance are greatly enhanced. Coupled with precise CNC machining, high precision and stability are ensured, allowing the product to have a longer service life in various industrial environments.

CNC Precision Machining

CNC Precision Machining

The high-precision machining method of Through Bore Rotary Union through computer numerical control machine tools can ensure that the size and shape of each component are very accurate. The material can be precisely cut, milled, drilled and other operations can be performed according to the design requirements to ensure that the various components of the Through Bore Rotary Union are perfectly matched, reduce friction and errors, and improve the stability and durability of the product. Using CNC precision machining can ensure that the product performs better under high load and high speed operation.

Anodizing

Anodizing is a process of forming an oxide film on the metal surface through electrolytic reaction, which is commonly used for metal materials such as aluminum alloys. Through this treatment, the oxide film formed on the surface not only enhances the corrosion resistance of the metal, but also improves the surface hardness and wear resistance. For Through Bore Rotary Union, anodizing can effectively prevent corrosion, improve the stability and service life of the product in harsh environments, and enhance the surface scratch resistance to ensure efficient operation in long-term use.

Support customer customization

We can flexibly adjust the design of Multi Passage Rotary Union according to your specific needs. Whether it is the aperture size, the number and configuration of circuit channels, or the type of transmission medium (such as current, signal, gas or liquid), it can be personalized according to your equipment needs. This ensures that the product is perfectly adapted to different application scenarios, providing higher work efficiency and better performance.

Through-hole structure design, can adapt to complex structures such as shaft-through cables

Adopt high-precision imported bearings, stable operation, low noise

Support high current, explosion-proof structure design, can adapt to high-risk environments

High-temperature resistant materials, adapt to harsh working conditions, such as high-temperature smelting equipment, etc.

Product life is up to 20 million revolutions, stable and reliable

Advantages

360° infinite continuous rotation

The 360° infinite continuous rotation of the Through Bore Rotary Union can continue to rotate 360 degrees without any interruption. It is suitable for application scenarios that require long-term and stable rotation, such as robots, automation equipment, medical devices or other high-frequency rotation mechanical systems.

High speed, high stability

The use of precision bearings and high-quality materials can maintain stability during high-speed rotation, ensuring that the equipment runs smoothly at high speeds. Whether in robots, automation equipment, or other systems that require high-speed continuous rotation, the Through Bore Rotary Union can provide reliable signal, current or media transmission to avoid failures caused by vibration or friction.

Multi-media transmission capability

The Through Bore Rotary Union can transmit multiple media at the same time, including current, signals, gases and liquids. Through specially designed multiple independent channels, each channel can transmit different types of media without interfering with each other.

Adapt to complex industrial environments

With industrial characteristics such as high current transmission, explosion-proof certification, and high temperature tolerance

Modular design, support customization

Multi-channel structure, high-speed signal ring, and thermal fluid channel can be configured according to user needs

Application areas

Automation equipment and robot joints

Realize continuous rotation of the arm for power supply and signal control

Wind power generation system

Transmit power and monitoring signals, suitable for high-power transmission

Packaging, printing, winding equipment

Solve the problem of high-speed rotation under complex processes

Medical imaging equipment (CT/MRI)

Realize high-speed interference-free data transmission and energy supply

Military radar and aviation systems

Meet the needs of high-precision and high-reliability transmission

Ocean detection and rotating platform

Can withstand humid, high-pressure and corrosive environments

FAQ

Will the Through Bore Rotary Union overheat at high speeds?

By using high-precision bearings and high-quality materials, the Through Bore Rotary Union is designed to effectively reduce friction and heat accumulation. At high speeds, it has good heat dissipation performance, which can maintain stable operation and prevent overheating. However, if it works at extreme high speeds, it is recommended to check the heat dissipation system regularly to ensure long-term and efficient operation.

How to deal with the problem of unstable current transmission in the Through Bore Rotary Union?

Unstable current transmission may be caused by poor contact or wear between the brush and the slip ring. It is recommended to check the wear of the brush regularly and replace it as needed. If it is a signal transmission problem, check whether the connection line is loose and ensure stable contact between the slip ring and the brush.

Is the Through Bore Rotary Union suitable for all types of liquid and gas transmission?

The Through Bore Rotary Union is generally suitable for the transmission of a variety of gases and liquids, including air, oil, coolant, etc., but not for highly corrosive or flammable and explosive media. When selecting, it is recommended to ensure the sealing performance of the product and the corrosion resistance of the material according to the type of transmission medium and working conditions.

Why do I get air or liquid leaks when using a Through Bore Rotary Union?

Air or liquid leaks are usually caused by worn seals or improper installation. Check seals and connections regularly to ensure they are securely installed and free of damage. Avoid using too high an operating pressure, especially in applications with large pressure fluctuations, to ensure good sealing performance.

How can I extend the service life of a Through Bore Rotary Union?

To extend the service life, it is recommended to perform regular maintenance checks, especially for wear of brushes and slip rings. Keep rotating parts lubricated, ensure that passages are not blocked, and regularly check that the sealing system is intact. In addition, avoid running at too high a speed or with too much load to reduce the loss of the product.

If a Through Bore Rotary Union fails, how can I troubleshoot the problem?

First, check that the rotating part is smooth and that the contact between the brush and the slip ring is normal. Check that the transmitted current or signal is stable and that there is no electrical interference or poor contact. If it is a gas or liquid transmission problem, check if the seal is damaged or the connection is loose. If troubleshooting is difficult, it is recommended to contact the manufacturer for professional testing and repair.